This year’s iarigai – IC annual scientific conferences jointly took place in Athens, Greece during September 19-24. They covered innovation and evolution in research, industry and education of the graphic communication, print, media, and packaging sectors.

bel was one of the sponsoring companies invited to deliver a keynote speech and shared its vision on The Connected Converter.

Having acknowledged the challenges that converters face, bel provides optimum solutions and services that make it easy for converters to leverage data across the entire production workflow, seamlessly automate processes and connect people and equipment.

We take pride in developing our flagship product, Overprint MIS, around these 3 pillars: Digitization – Automation – Connectivity.

Digitization

Digitization of the processes and workflows enables your business to exchange information more effectively, empowers interaction between people and equipment, enables the collection of data, provides an end-to-end view to all connected parties, establishes trends, and makes better & faster decision-making.

This in turn increases overall efficiency, making your business more agile, delivering services at speed, ease of access, and convenience. More importantly, it allows your print business to be driven by data and you, as a business owner, to make fact-based decisions.

Automation

By automating every production step and process, your entire production line runs smoothly. The benefits when automating your workflow are raising your output, additional increase of short runs production, eliminating bottlenecks & human errors, increased quality, savings of time and manpower.

Converters can start small in automation steps and include additional levels of automation as their business grows, or as people are getting familiar to the automation process. Management Information Systems should be developed for this task, whereas you can bring automation to key touch points in the production workflow. Automation can be added on every individual task by applying Industry 4.0 and JDF standards to the print lifecycle.

Connectivity

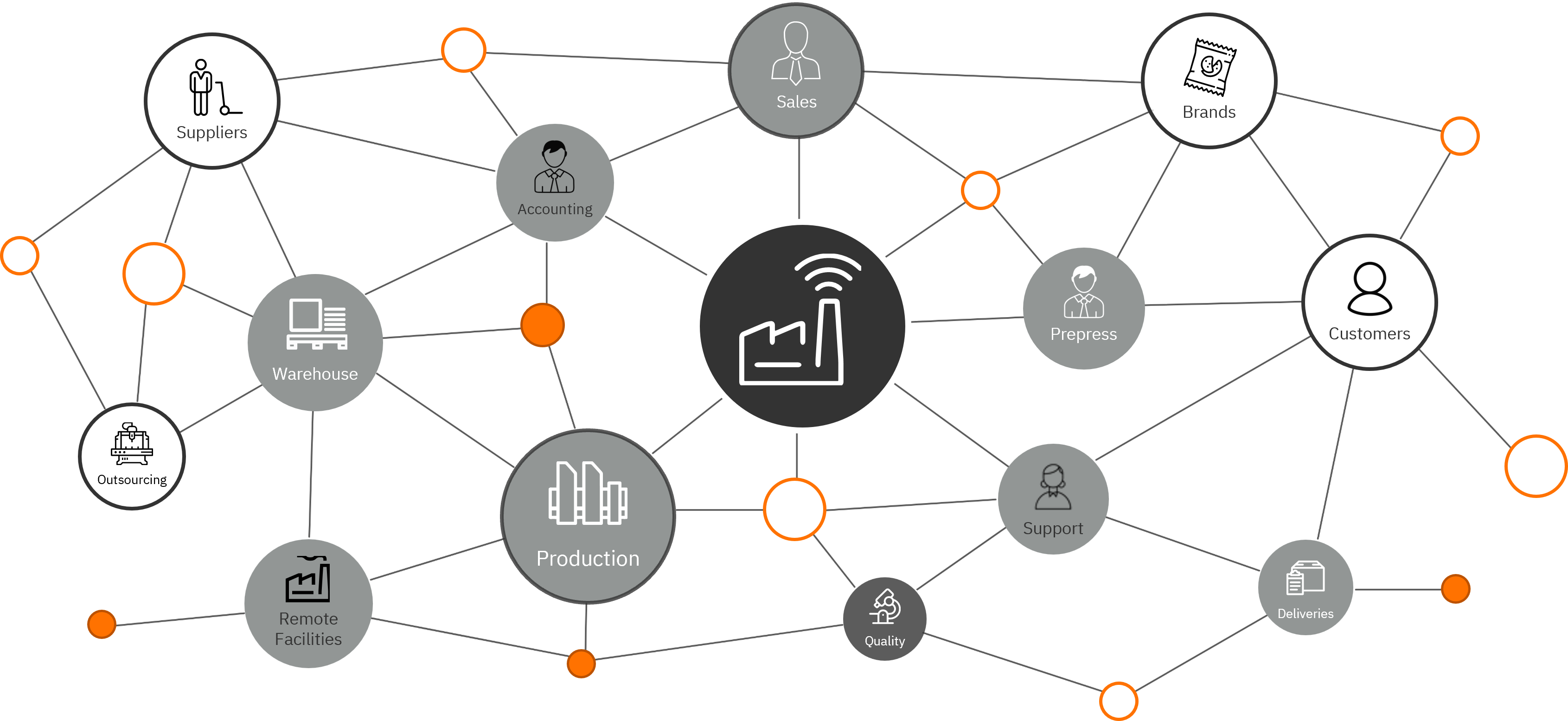

In the newly established environment information exchange should be on the spot, decision-making needs to be based on data and done fast, bottlenecks and errors to be eliminated. This means that the supply chain for the conversion of a product should be connected in a seamless way leveraging the internet capabilities, allowing continuous connectivity and exchange of information.

All parties involved to the conversion of a product need to have a complete overview of the production process as well as established ways of exchanging information, workflows for approval of job tickets and processes, etc. Continuous access to online systems allows the management of the workflow, data, and communication channels.

Thus, the entire production line, from the creation of the pdf file to the final product, is connected. In this environment, people and equipment are talking to each other seamlessly, transmitting data online. Eventually, the processes are completed as designed, repeating accurately every time.

Overprint MIS, developed upon the principles of the 3 pillars works as the core management system ensuring an efficient and optimized converting process. Its exhaustive, modular, and strongly customizable architecture makes it an ideal fit for every industry segment.

One thought on “Our vision: THE CONNECTED CONVERTER”

Comments are closed.