bel Information Systems, developer of Overprint MIS for the printing & packaging industry, has marked 25 years of continuous evolution with a strong customer focus, committed to ensuring full business coverage.

Founded in 1998 in Athens, Greece, bel started its journey with an ambitious vision of providing professional services to the graphic arts industry. Following successful recognition by the market for their eagerness and professionalism, and while bel identified a critical gap in managing business processes, in 2001 they initiated the development of Overprint.

The first release of the software was launched in 2004 for commercial printing, which was then in prosperous growth. At the time, the system mainly comprised a version of the cost estimation module, which over time underwent substantial enrichment expanding its functionality to include production management, warehouse management, automated data collection, several integrations, etc.

Since 2007, Overprint MIS has extended its reach into the packaging segment offering exceptional value proposition, as it had been designed specifically for packaging requirements. The software’s ongoing enhancements reflect its adaptability to evolving market demands solidifying its position as a pivotal player in the packaging landscape.

Another important milestone was the entry into the IML industry in 2011, covering extended order processing and ganging, while today Overprint is the only MIS whose segmented platform has been developed specifically for in-mould label printing. Equivalent specialization has been developed in the platform for labels in 2018, incorporating automated costing and production proposals. The year 2021 a historic deployment for bel took place, its largest-ever, as Overprint’s segmented platform was adapted for security printing.

bel’s commitment to delivering excellence and unparalleled value is ensured by a team of dedicated professionals who continue to fortify the organization’s growth track. As we celebrate 25 years of successfully managing the print lifecycle, bel remains dedicated to pushing boundaries, setting industry benchmarks, and ensuring sustainable value for its esteemed customers.

bel wins the Gold award in its category in the Printing Awards 2022 organized by Boussias Communications for the second time in Greece. Leading representatives of the printing & packaging industry gathered in the awards ceremony which took place on Wednesday, December 1st at the Radisson Blu Park hotel in Athens. Specifically, bel received the Gold award for the integrated solution of Overprint’s Control Center in the category Production management systems and quality control in printing.

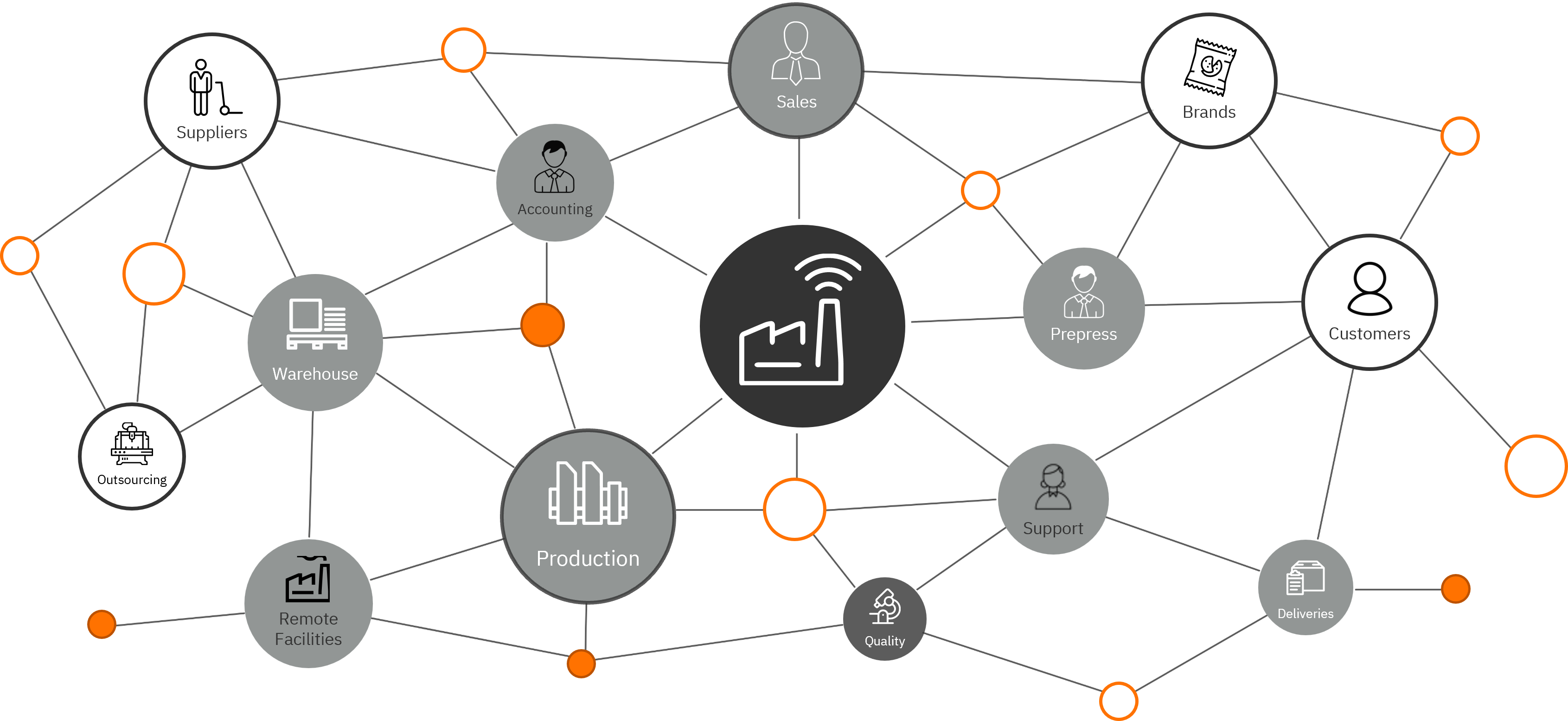

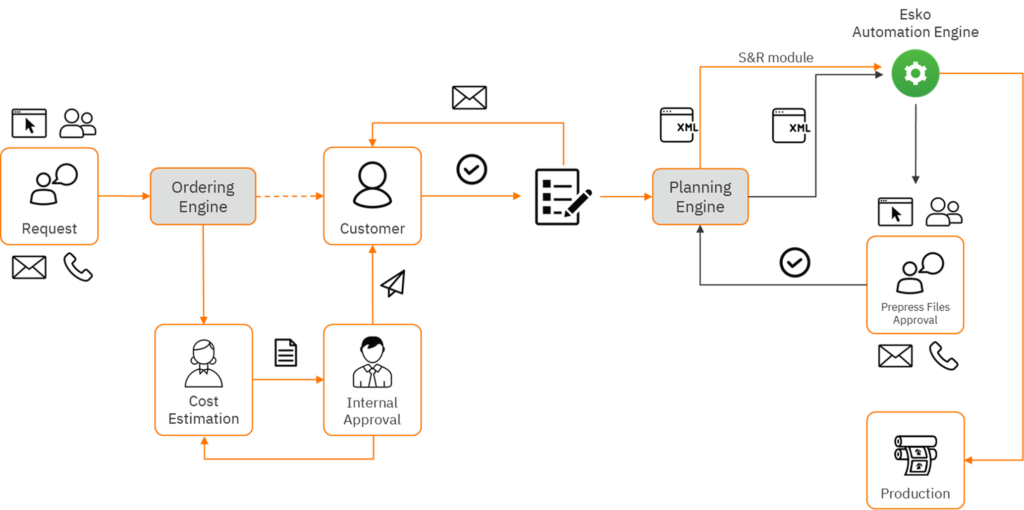

bel wins the Gold award in its category in the Printing Awards 2022 organized by Boussias Communications for the second time in Greece. Leading representatives of the printing & packaging industry gathered in the awards ceremony which took place on Wednesday, December 1st at the Radisson Blu Park hotel in Athens. Specifically, bel received the Gold award for the integrated solution of Overprint’s Control Center in the category Production management systems and quality control in printing. Nowadays, there is a newly established environment where digitization, automation, and connectivity play an important role in today’s value chain. Overprint MIS and the aforementioned Overprint Control Center automation solution have been developed and designed upon the principles of the 3 pillars of our vision of The Connected Converter which are: Digitization – Automation – Connectivity.

Nowadays, there is a newly established environment where digitization, automation, and connectivity play an important role in today’s value chain. Overprint MIS and the aforementioned Overprint Control Center automation solution have been developed and designed upon the principles of the 3 pillars of our vision of The Connected Converter which are: Digitization – Automation – Connectivity.