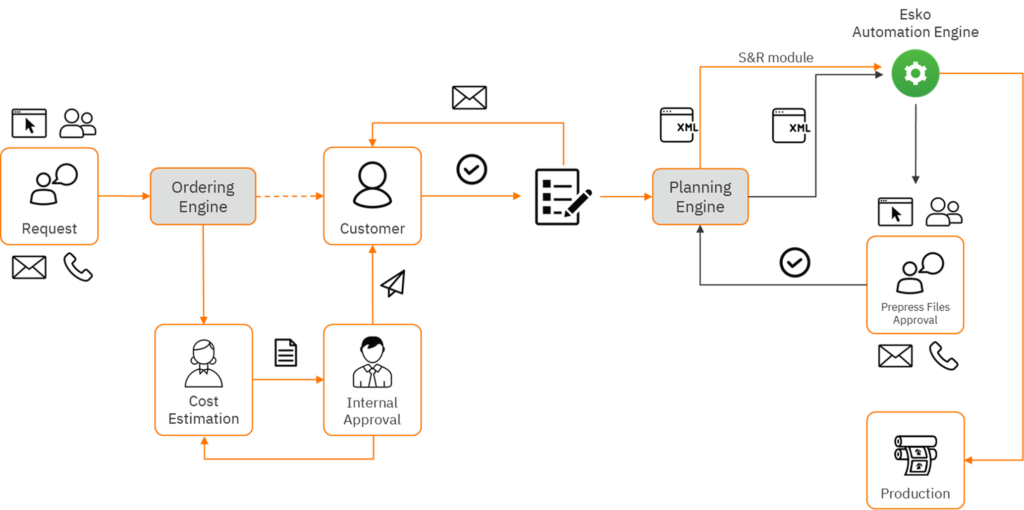

When it comes to integrations with other systems, bel’s team of business consultants could not find a better opportunity than to integrate Overprint MIS with Esko’s Automation Engine. The implemented solution involves a 2-point integration with Esko Automation Engine, the first with the prepress and the second with the production process.

Overprint MIS being the core management system within an organization generates the codification by which the products and orders are logged and communicated within the company’s organizational structure. The integration allows the interaction of Overprint MIS and Esko Automation Engine via Automation Engine’s Connect, enabling the sharing of data within the whole organization.

Which is the functionality of the solution

Overprint MIS communicates the job’s technical specifications to Automation Engine, where a prepress job is created using the very same data. Alongside, the product is also created within Esko Automation Engine using the codification sourced by Overprint. This means that job creation in Automation Engine can be initiated from within the MIS. The data comprises the product number, description, customer information, and product specs such as the number of colors, die-cut plate number, substrate information, etc. The prepress department works on the same data set as the customer service team and the same information is moved forward to the production floor.

Following the approval of artwork, the job ticket generated in Overprint MIS is also submitted to the Layout module of Esko Automation Engine where the Step & Repeat (S&R) is performed. This functionality can apply to both a single-product job or a job containing several products, a job that is created using the Orders Ganging functionality in Overprint MIS. In the latter case, there will be more than one product in the same job ticket. The information transmitted is the product(-s) ID, product type(-s), quantities per product type, die-cut plate info, customer service information, and other metadata. This info will be matched to the product that was created in Esko Automation Engine by the previous integration step. After the S&R is performed, a production job is created and sent to the production department for printing. The production job is designed with a predefined structure and job parameters, according to the needs of production.

Benefits delivered with the integration

- Automation with the minimum of user intervention eliminates the need to input data manually into Esko Automation Engine; this further streamlines and automates the overall job processing, which in turn increases efficiency.

- Eliminates errors from manual entries.

- Use of one point of reference enables the seamless interaction among customer service, prepress, and production departments.

- Linking MIS job tickets with Esko Automation Engine products increases productivity and responsiveness, and eventually, it helps provide better customer service and satisfaction.

- Higher productivity will increase your organization’s overall production capacity.

This integration is opening up a wealth of opportunities for our customer base. Overprint MIS supporting all industry segments and any production line within the same platform means the integration solution can be scaled to any environment.